Energy Services provides a wide array of services through its subsidiary companies including. Small containments are also frequently needed for fuel storage pump containments and short term frac tank storage.

Diameter x Height 20.

. Upstream Facilities Typical Tank Battery 9. From 20 to 780 barrel tanks ESPS can help you keep your well pumping ESPS will also supply all of your stair and catwalk necessities. The roots of Squibb Tank Company are in the Illinois Basin oil fields and we have established the reputation of delivering the highest quality products.

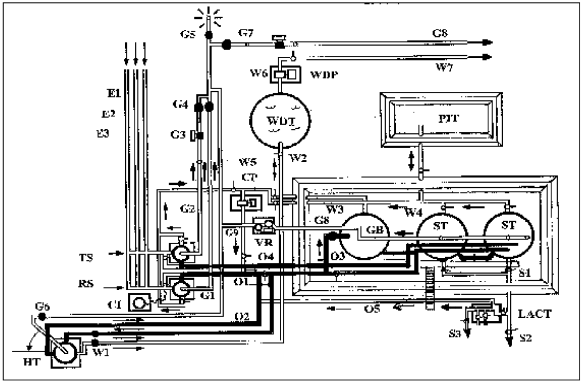

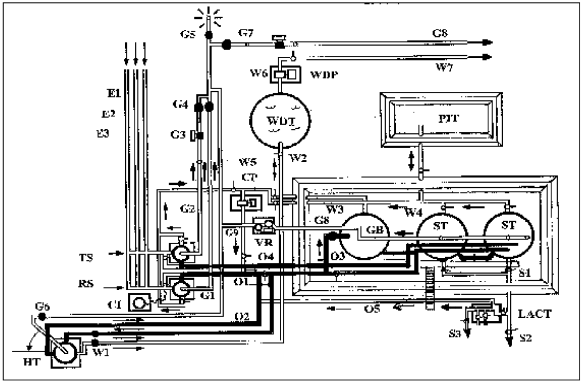

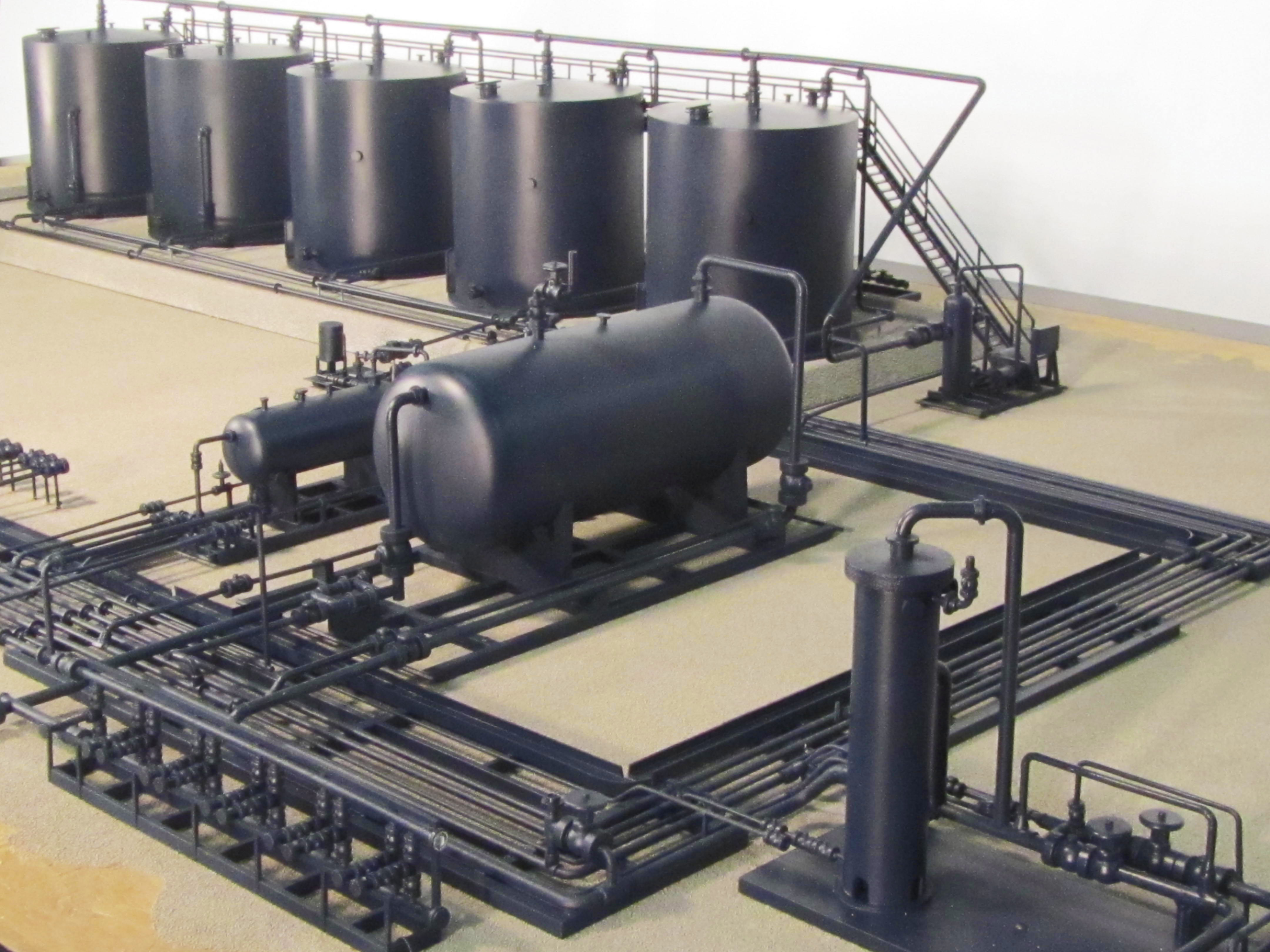

Since 1991 many thousands of these HWSB Skim Tanks have successfully replaced gunbarrel tanks separating and capturing over 99 of all entrained oil in the produced water fed into them. In the tank battery oil volume is measured and tested before pumping the oil into the pipeline system. An oilfield tank battery is the combination of surface vessels gathered in one place to process a well stream into sellable or disposable products.

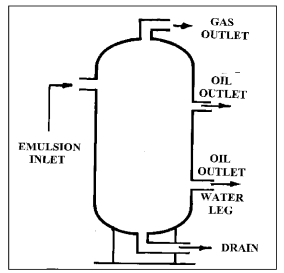

Production Facilities A group of tanks that are connected to receive crude oil production from a well or a producing leaseA tank battery is also called a battery. For tanks configured in a battery EPA vapor recovery requirements may stipulate that each tank may need to be rated up to 16 ounces of air pressure with a 16-ounce thief hatch. This tank is designed to separate very small quantities of oil from very large quantities of water.

Upstream Facilities 24 Well Condensate Facility 11 Note the solar panes cable tray and other electrical components. Depending on your system a battery may connect to one well or process several of them and even that can change over time. Sandblasting and Powder Coating.

Fatal Oil Field Injuries. It gives undergraduate and graduate petroleum engineering students hands-on experience in the design and operation of typical oilfield equipment. It is known as the HWSB Skim Tank.

Tank batteries involve the storage and processing tanks flow lines and any other equipment necessary to operate oil and gas wells. Designed with rugged external packaging to fit within a confined tool space it must tolerate extreme temperatures while withstanding high shock and vibration. All LFM oilfield tanks used for this purpose are available in reinforced configurations that easily comply with the applicable EPA regulations for vapor recovery.

A tank battery is a group of connected tanks that receive crude oil production from a well or a producing lease. Available in five sizes ranging from 125- to 4-in the XL Series pumps have flow capacities that vary from 4 to 345 gpm 15 - 1306 Lmin. Located just 15 minutes away from the main Texas Tech campus the Oilfield Technology Center is a unique educational facility designed to serve both research and teaching needs.

Tank Specifications Capacity Dimensions. Oilfield Supply and Pump Shop. Constructed of shock resistant ductile iron the pumps feature a wide range of mechanical seal components and different vane and.

For your next oilfield tank battery contact ESPS. In the tank battery the oil volume is measured and tested before pumping the oil into the pipeline system. Tank Batteries Explained.

Whether your storage needs include upgrading a battery of tanks building an entirely new site or replacing a single tank trust in Squibb Tank Companys experience in the oilfield to deliver the very best products. A tank battery is also sometimes called a battery. Our standard design Gunbarrel tanks come with flume pipe assembly spreader table waterleg outlet with tie down brackets API 5L threaded couplings 4.

The process of oil tank battery installation. Econdary containments prevent hazardous liquids from spilling and contaminating soil and water making them necessary for tank battery sites saltwater disposal wells gas processing facilities and salt mines. Unlike a conventional battery an oilfield battery must safely provide power sufficient to enable a tool to perform as specified even on extended jobs.

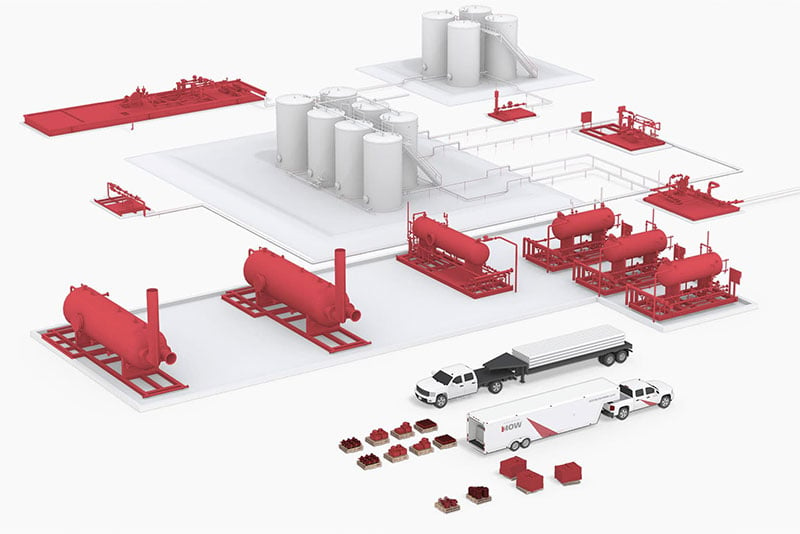

Gunbarrel tanks are an excellent choice for Tank Batteries when atmospheric pressure gravitational force and retention time are sufficient for the adequate separation of oil water and gas. Tank battery solutions Electrical discharge and subsequent explosive detonation of the ullage inside chemical storage tanks In recent years there has been a growing trend in the use of fiberglass storage tanks in the oil and gas industry. Upstream Facilities 12 Well Gas Facility 10 Note that this facility does not have electrical equipment.

Specifically built for tank battery circulation applications.

Oilfield Facility Construction Action Energy Services

Tank Battery Intro Overview Oil Gas Training Basics Youtube

The First Few Tanks In A Tank Battery In Oil Gas Production By Marlee Rose Medium

Flow Of Crude Oil Through The Tank Battery In Oil Gas Production By Marlee Rose Medium

Tank Batteries Production Facilities Distributionnow

Tank Battery Design In Oil Gas Production Greasebook

2 364 Tank Battery Stock Photos Pictures Royalty Free Images Istock

0 comments

Post a Comment